Resistance Monitoring

Resistance based monitoring is the most complete wrist strap monitoring system available. Workstations using resistance monitors are almost never at risk. Basic systems use impedance technology and single wire wrist straps which can be easily fooled. If a wrist strap is worn incorrectly, the monitor can still register a “pass†condition or if the wire of the wrist strap is severed the workstation could be put at risk for ESD damage. Dual conductor wrist bands offer fail safe protection because the monitor will alarm if the operator looses contact with one ground wire. It is very rare to loose both ground wires at the same time, so the workstation is still protected even during a alarm condition. The CM2800 series from Transforming Technologies is a high quality resistance monitor and provides continuous monitoring of two operators, two mats, or two grounded workstation tools.

CM2800 Dual Wire Constant Monitor

A New Cost Effective Source

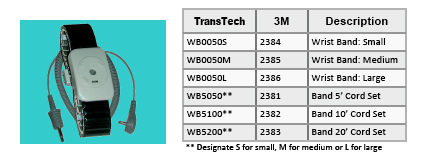

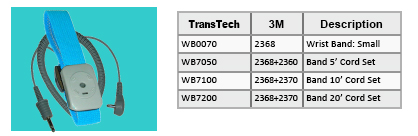

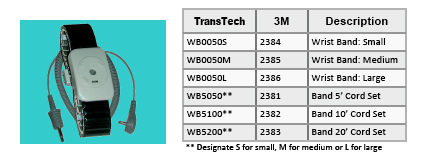

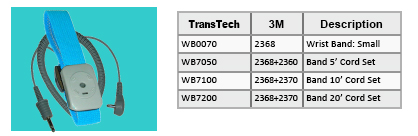

For many years, resistance monitoring and dual conductor products were limited to mainly 3M. But Transforming Technologies now offers a value alternative for these premium 3M* dual conductor products. We incorporate the best design elements of expired patent # 5,018,044 with our own experience making premium quality ESD products to produce the WB5000, WB7000 to be used with the resistance monitor CM2800 series. Transforming Technologies and 3M’s dual conductor products are functionally equivalent*. The wrist bands, coil cords and resistance monitors can be used together in any combination!

Both 3M and Transforming Technologies’ Speidel metal band feature two 180 de-gree conductive paths around the wrist, providing maximum skin contact. The expandable band is constructed with two stainless steel back plates and is available in small, medium and large sizes.

Transforming Technologies and 3M’s fabric wrist strap features a band made of a silver plated, monofilament, continuous thread woven together with elastic nylon to maintain full conductivity, comfort and reliability, while providing rapid and con-tinuous drain of static charge.

Coil Cords

Used in conjunction with dual conductor constant workstation monitors, Transforming Technologies’ CC3000 series dual conductor coil cords provide unmatched reliability and value. A double insulated jacket provides incredible durability and a wide diameter straight plug makes it easy to insert and remove the cord from a remote input jack. The coil cord come standard in 5’, 10’ or 12’ lengths and are functionally equivalent to the 3M coil cords.

*Compatibility with particular resistance monitors should be verified.

*Compatibility with particular resistance monitors should be verified.

For information on resistance monitoring, dual conductor grounding products or any general questions, please contact Transforming Technologies at 419-841-9552 or email at info@transforming-technologies.com.