LED light technology saves money, time and benefits workers well being.

While you won’t find LEDs in too many household lighting  fixtures these days, there are a several great reasons why you will want to use them in your business.

First, there’s the reduced energy use. The LED method of producing light loses far less energy to heat than do other lighting technologies. It’s dramatically more efficient than the vacuum/filament method used in incandescent bulbs — sometimes around 85 percent more efficient; and it’s even about 5 percent more efficient than the CFL’s plasma-tube approach [source:Â Taub].

A single light fixture stocked with a 60-watt incandescent bulb consumes about 525 kWh of electricity in a year; put a GeoBulb LED bulb in that light fixture, and the annual energy use is more like 65 kWh [source:Â Sundance]. The annual CO2 reduction is in the hundreds of pounds for a single lamp.

But energy-efficiency is just part of the story. The other part is time-efficiency: You could go 20 years without having to change an LED light bulb. Solid-state lights like LEDs are more stable light sources than incandescent or fluorescent bulbs, and the difference is startling: A typical incandescent bulb lasts about 750 hours; a Geobulb lasts 30,000 hours [source:Â Sundance].

Layton, Julia. “How LED Light Bulbs Work” 23 July 2009. HowStuffWorks.com. <http://science.howstuffworks.com/environmental/green-tech/sustainable/led-light-bulb.htm>  27 February 2013.

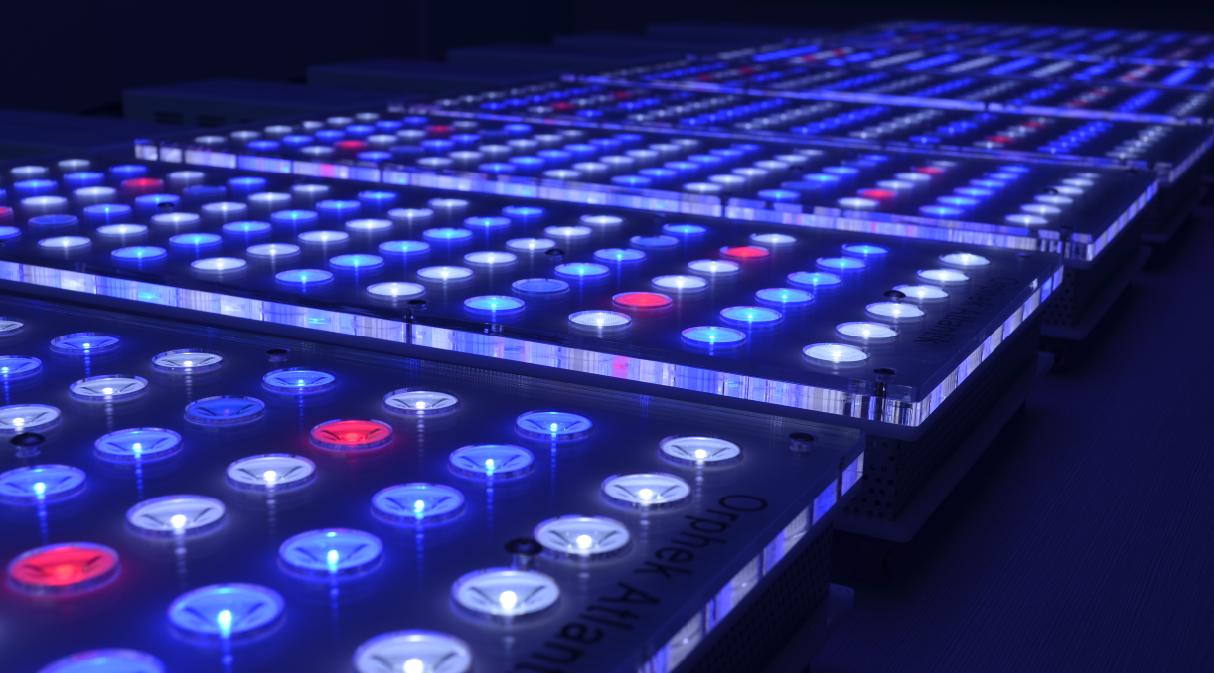

Transforming Technologies acknowledges the advantages of LED lights and have incorporated them into the BFN Overhead Ionizers. More information on the BFN LED ionizers here.

Top 10 Benefits of LED Lighting

1. Long Life

Long life time stands out as the number one benefit of LED lights. LED bulbs and diodes have an outstanding operational life time expectation of up to 100.000 hours. This is 11 years of continuous operation, or 22 years of 50% operation. If you leave on the LED fixture for 8h per day it would take around 20 years before you’d have to replace the LED bulb.

LED’s are different to standard lighting: They don’t really burn out and stop working like a standard light, moreover the lighting diodes emit lower output levels over a very long period of time and become less bright.

LEDs are extremely durable and built with sturdy components that are highly rugged and can withstand even the roughest conditions. Because LED lights are resistant to shock, vibrations and external impacts, they make great construction or manufacturing lighting systems for rough conditions and exposure to weather, wind, rain or even external vandalism.

2. Energy Efficiency

With traditional incandescent light bulbs who operate at 20% energy efficiency only, 80% of the electricity is lost as heat. Imagine the following scenario:

If you use traditional lighting and have an electricity bill of US$ 100, then US$ 80 of that money has been used to heat the room, not to light it! Using LED illumination with 80% efficiency, the electricity costs would be around US$ 20 and you’d have saved around US$ 80.

The long operational life time acts as a multiplicator and helps achieve even more energy efficiency, especially large scale and when thinking in terms of urban infrastructure projects, such as cities, railroads and airports.

Think for example, an airport using energy efficient LED lighting exclusively and achieving a 30% power consumption reduction in comparison with an airport using conventional lighting technology. You’ll see that you can make significant energy savings also when it comes to maintenance and replacement due to the long operational life times of LED lighting. Think of all the work and energy it would take to purchase, stock and change the conventional light bulbs of an airport

3. Workplace Lighting Issues

Eyestrain is the number one health-related complaint of office workers and improper lighting levels are associated with vision problems such as eyestrain, dry eyes, and itchy/irritated eyes. This can be alleviated with proper task lighting which becomes much more important as our eyes age, especially for precision work. Also, there is a human benefit to LED task lighting: Improved productivity and improve mood and energy levels are reported at business with proper lighting

4. Ecologically Friendly

LED lights are free of toxic chemicals. Most conventional fluorescent lighting bulbs contain an abundance of materials like mercury that are dangerous for the environment.

LED lights contain no toxic materials and are 100% recyclable, and will help you to reduce your carbon footprint by up to a third. The long operational life time span mentioned above means also that one LED light bulb can save material and production of 25 incandescent light bulbs. A big step towards a greener future!

5. Zero UV Emissions

LED illumination produces little infrared light and close to no UV emissions. Because of this, LED lighting is highly suitable not only for goods and materials that are sensitive to heat due to the benefit of little radiated heat emission, but also for illumination of UV sensitive objects or materials such a in museums, art galleries, archeological sites etc.

6. Design Flexibility

LEDs can be combined in any shape to produce highly efficient illumination. Individual LEDs can be dimmed, resulting in a dynamic control of light, color and distribution. Well-designed LED illumination systems can achieve fantastic lighting effects, not only for the eye but also for the mood and the mind:

LED mood illumination is already being used in airplanes, classrooms and many more locations and we can expect to see a lot more LED mood illumination in our daily lives within the next few years.

7. Operational in Extremely Cold or Hot Temperatures

LED are ideal for operation under cold and low outdoor temperature settings. For fluorescent lamps, low temperatures may affect operation and present a challenge, but LED illumination operates well also in cold settings, such as for outdoor winter settings, freezer rooms etc.

8. Light Dispersement

LED is designed to focus its light and can be directed to a specific location without the use of an external reflector, achieving a higher application efficiency than conventional lighting. Well-designed LED illumination systems are able to deliver light more efficiently to the desired location.

9. Instant Lighting & Frequent Switching

LED lights brighten up immediately and when powered on, which has great advantages for infrastructure projects such as traffic and signal lights.

Also, LED lights can switched off and on frequently and without affecting the LED’s lifetime or light emission. In contrast, traditional lighting may take several seconds to reach full brightness, and frequent on/off switching does drastically reduce operational life expectancy.

10. Low-Voltage

A low-voltage power supply is sufficient for LED illumination. This makes it easy to use LED lighting also in outdoor settings, by connecting an external solar-energy source and is a big advantage when it comes to using LED technology in remote or rural areas.

hand logging of wrist straps and tabletop material performance that is required is a cumbersome, labor-intensive paperwork nightmare. Use of our

hand logging of wrist straps and tabletop material performance that is required is a cumbersome, labor-intensive paperwork nightmare. Use of our